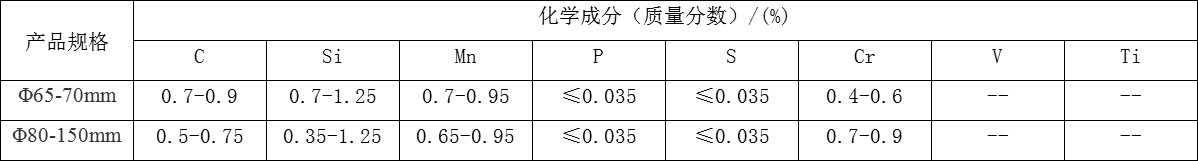

Note: trace elements such as V, Ti and B are allowed.

Note: FB forged ball: for Φ 65-80mm ball mill, the effective height difference is 8.5m; for Φ 90-150mm ball mill, the effective height difference is 10m.

Case analysis of HMR forging grinding ball

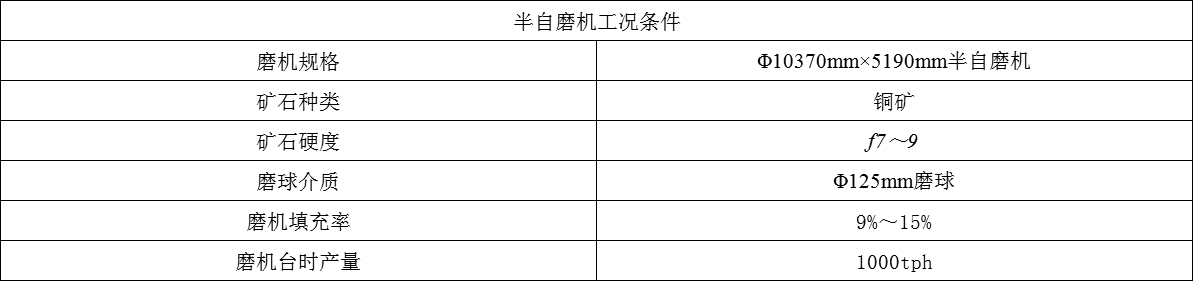

There are two series of grinding operation in a copper mine concentrator in Jiangxi Province. The specifications of the two semi autogenous mills are the same, and the operating conditions are completely the same. Series 1 adopts Φ 125mm forged grinding balls produced by HMR group, and series 2 adopts grinding balls from other manufacturers.

Φ 10370mm × 5190mm semiautogenous mill Φ 125mm HMR forged grinding ball

After 2 months of operation, the statistical analysis of the application effect of HMR forging grinding ball is as follows::

The average ball consumption of HMR forging ball is 490 g / T, and that of other manufacturers is 620 g / T. the unit ball consumption is reduced by 20.9%.

HMR forged grinding ball shows perfect combination of hardness and toughness, low wear rate, low crushing rate and no loss of roundness.