Case analysis of HMR casting high chromium grinding ball

There are two series of grinding operations in a molybdenum ore dressing plant in Henan Province. The two ball mills have the same specifications and the operating conditions are completely the same. Series 1 uses high chromium grinding balls produced by HMR group, and series 2 uses low chromium balls from other manufacturers.

After one month of operation, the statistical analysis results of HMR high chromium grinding ball are as follows:

The average ball consumption of HMR high chromium cast ball is 660 g / T, and that of other manufacturers low chromium cast ball is 1000 g / T. the unit consumption of grinding ball is reduced by 34%.

Compared with the low chromium ball, the high chromium ball has lower crushing rate, which improves the mill output and reduces the labor intensity of workers.

Φ 4800 mm × 7000 mm ball mill

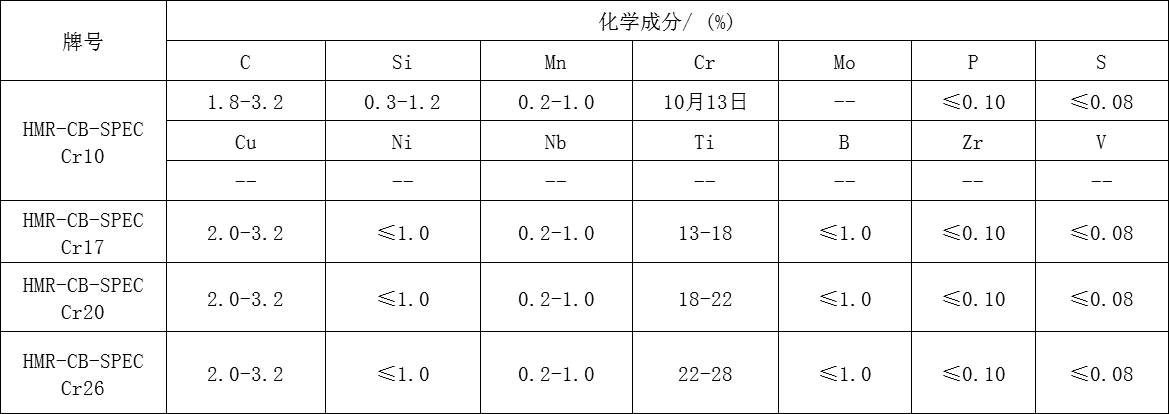

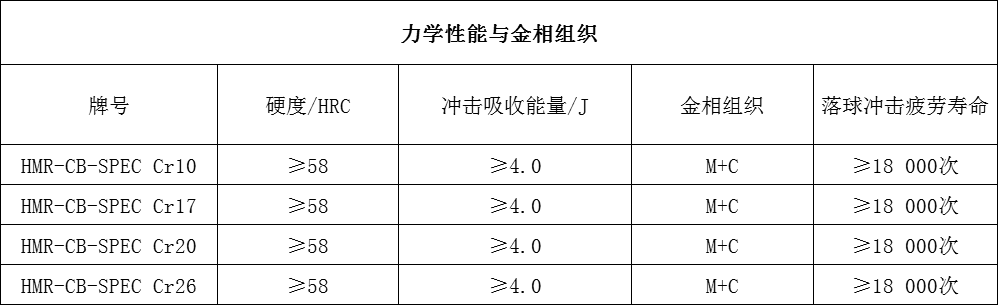

High chromium grinding ball