*The effective height difference of falling ball test is 10m, without breakage and roundness

Before falling ball test

After 40 000 drops

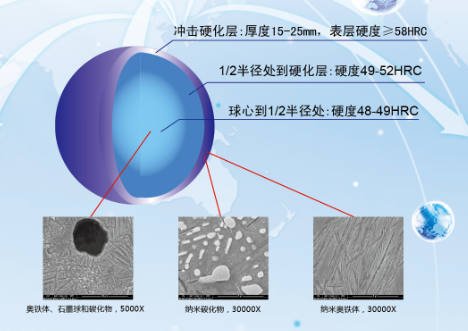

HMR NMCADI+10Case analysis of grinding ball

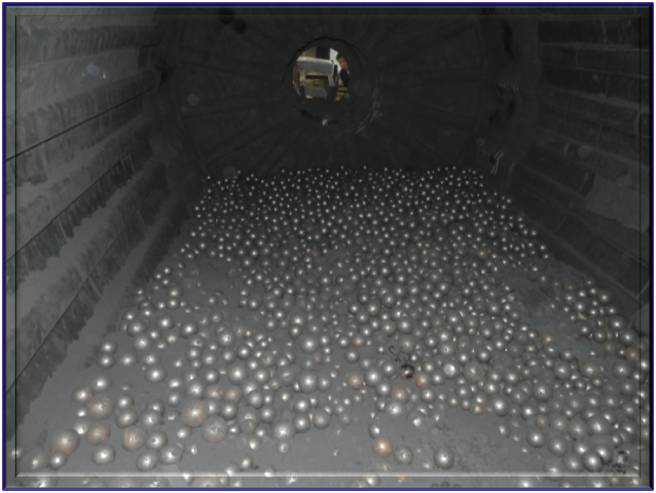

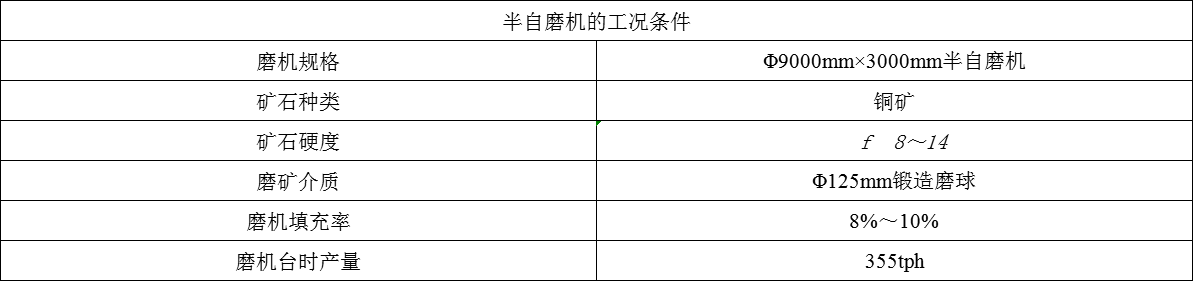

There are two series of grinding operations in a copper ore dressing plant in Mongolia, two semi autogenous mills with the same specifications, and the operation conditions are completely the same. Series 1 adopts Φ 125mm nmcadi + 10 grinding balls produced by HMR group, and series 2 adopts Φ 125mm forged grinding balls produced by other manufacturers.

Φ9000mm×3000mmSemi autogenous mill

After 1.6 months of operation, the statistical analysis results of grinding ball use effect are as follows:

The average ball consumption of HMR nmcadi + 10 grinding ball is 327 g / T, and that of other manufacturers is 786 g / T. the unit ball consumption is reduced by 58.4%.

HMR nmcadi + 10 grinding ball shows the perfect combination of hardness and toughness, work hardening in the process of use, low wear rate, low crushing rate and no loss of roundness.

HMR Φ125mm NMCADI+10Grinding ball